-

Ρίψη κραμάτων αργιλίου

-

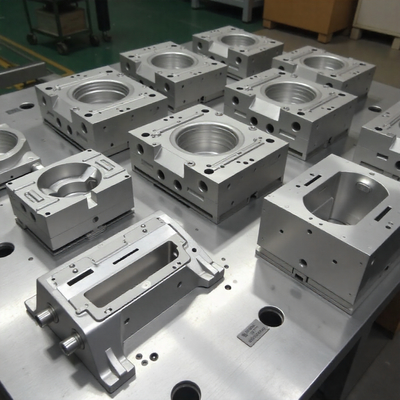

Φόρμα ρίψεων κύβων πίεσης

-

καλούπια χύτευσης μετάλλων

-

Αλουμινίου χύτευση καλουπιών

-

EPS φόρμα αφρού

-

Χαμένη φόρμα αφρού

-

Φόρμα ρίψεων άμμου

-

μόνιμο καλούπι χύτευσης αλουμίνιο

-

Αλουμινίου Die Gravity Casting

-

Χυτή κύβος σχεδίαση αργιλίου

-

Φόρμα μερών αυτοκινήτου

-

Μούχλα Multi κοιλότητα

-

Φόρμα κεφαλιών κυλίνδρων

-

φόρμα υψηλής ακρίβειας

-

Γρήγορη τρισδιάστατη υπηρεσία εκτύπωσης

-

Greg HenkΕυχαριστίες για ευγενικά τη φιλοξενία σας. Η επιχείρησή σας είναι πολύ επαγγελματική, θα έχουμε τη συμπαθητική συνεργασία στο κοντινό μέλλον.

Greg HenkΕυχαριστίες για ευγενικά τη φιλοξενία σας. Η επιχείρησή σας είναι πολύ επαγγελματική, θα έχουμε τη συμπαθητική συνεργασία στο κοντινό μέλλον. -

Λιονέλ LoboΚαλή επιχείρηση με τη συμπαθητική υπηρεσία και υψηλός - ποιότητα και υψηλή φήμη. Ένας από τον αξιόπιστο προμηθευτή μας, αγαθά είναι παραδοθείσα έγκαιρη και συμπαθητική συσκευασία.

Λιονέλ LoboΚαλή επιχείρηση με τη συμπαθητική υπηρεσία και υψηλός - ποιότητα και υψηλή φήμη. Ένας από τον αξιόπιστο προμηθευτή μας, αγαθά είναι παραδοθείσα έγκαιρη και συμπαθητική συσκευασία.

Aluminum Die Casting Molds | CNC Machining, Permanent Mold & Sand Casting Solutions for Industrial Application

Επικοινωνήστε μαζί μου για δωρεάν δείγματα και κουπόνια.

WhatsApp:0086 18588475571

WECHAT: 0086 18588475571

Skype: sales10@aixton.com

Εάν έχετε οποιαδήποτε ανησυχία, παρέχουμε τη 24ωρη σε απευθείας σύνδεση βοήθεια.

x| Όνομα προϊόντος | μόνιμη ρίψη φορμών | Απομνημόνευση | Αυτόματο |

|---|---|---|---|

| Χρησιμοποίηση της σκληρότητας | >HRC45 | Διάρκεια ζωής | 500.000-1.000.000 βολές |

| Μεταλλικό χρώμα | Μαύρο μέταλλο | Επιφανειακή επεξεργασία | Κατεργασία με θερμοκρασία |

| Μέσο πάχος τοίχου | > 3 mm | Στάνταρ | GB ASTM AISI DIN BS |

| Επισημαίνω | aluminum die casting molds for CNC machining,permanent mold casting aluminum solutions,industrial sand casting aluminum molds |

||

Aluminum Die Casting Molds | CNC Machining, Permanent Mold & Sand Casting Solutions for Industrial Application

We deliver exceptional value through permanent mold systems that optimize both initial investment and long-term operating costs. Our designs focus on efficiency, durability, and performance to ensure the lowest total cost of ownership in the industry.

Just give us your sample, drawing or ideas, our professional sales team and engineer team and our workshop staff can make a actual product you want.

Appliaction

-

Price-sensitive market segments

-

High-volume consumer products

-

Competitive industrial components

-

Value-engineered applications

-

Emerging market requirements

Aluminum Die Cast Mould Description

1. Drawing: Provide by customer, or design according as the sample.

2. ODM we have the client's idea or draft first,then our experienced engineer will build the best design and manufacturing technology.finally our sales will supply the verified design and solution to our client for confirming.

3. OEM that means Customer design or samples will be very welcome,we will follow client standard to manufacturing this product 100%.

Aluminum Die Cast Mould Proudct Range

|

Product Name

|

Aluminum mould die casting

|

||

|

Size

|

Customized

|

||

|

Color

|

As your requirements

|

||

|

Material

|

Aluminum

|

||

|

Application

|

Auto parts, Light fixture, lamp cover, led light housing, heat sink or any other type of die casting parts

|

||

|

Service

|

OEM/ODM

|

||

|

Product's Design

|

Customized as customers' drawings or samples

|

||

Manufacture Process

1. Review the part design,drawings and quality standard from clients.

2. Mould and Tooling design & manufacturing

3. Mould and Tooling testing & confirm the sample

4. Die casting raw castings

5. Surface treatment: Trimming,Deburring, polishing, cleaning, passivation & power coating and other requirement from Customer

6. Precision machining: CNC lathes, milling, drilling, grinding etc

7. Full Inspection

8. Packing

9. Delivery

Quality Control

1) Checking the raw material after they reach our factory------- Incoming quality control ( IQC)

2) Checking the details before the production line operated

3) Have full inspection and routing inspection during mass production---In process quality control(IPQC)

4) Checking the goods after they are finished---- Final quality control(FQC)

We strictly control production process by using computer to monitor 24/7, in order to enhance and stable the production quality. VCU has its own highly qualified QC team equipped with all necessary and state-of-the-art testing equipment to be able to perform 100% inspection in order to ensure the best quality products that will be delivered to all of our customers.

Packaging & Shipping

Our products are all packed in wooden cases to ensure zero damage. If customers have specific requirements for the packaging, we will gladly accommodate. The products will be sent to you on time and we will arrange everything from the initial consultation to the delivery of your chosen port anywhere the world. We can also customize the packing method according to customers' needs. Suitable for seaway transportation.

![]()

Our Advantages

-

Precision temperature control throughout casting process

-

Reduced cycle times through efficient heat extraction

-

Minimized thermal stresses in mold components

-

Consistent microstructure in cast components

-

Adaptable to various aluminum alloys

Company profile

Luoyang Liushi mould Co., Ltd was established on 2001, which is National Standard Setting Unit for Lost Foam Casting Mould. The company is located in the Millennium Emperor, peony flower city of Luoyang City. We have 9800 office building, and 22000 workshop, which is well equipped with research, development, design, foundry, machining, assembly, surface treatment and other equipment. It′s a Luoyang municipal R&D center and technology center.

Company technicians can provide on-site guide mould assembly, test production, free repair and complete technology for lost foam casting proecss according to customer demands. With the business philosophy of "careful design, lean manufacture, best service, perfect quality", we strive to provide satisfactory products and services for customers. After years of development, our company has become the preferred mould suppliers of many lost foam casting manufacturers and the exclusive supplier.

Calculate your savings! Use our online ROI calculator to see how our molds can reduce your production costs.